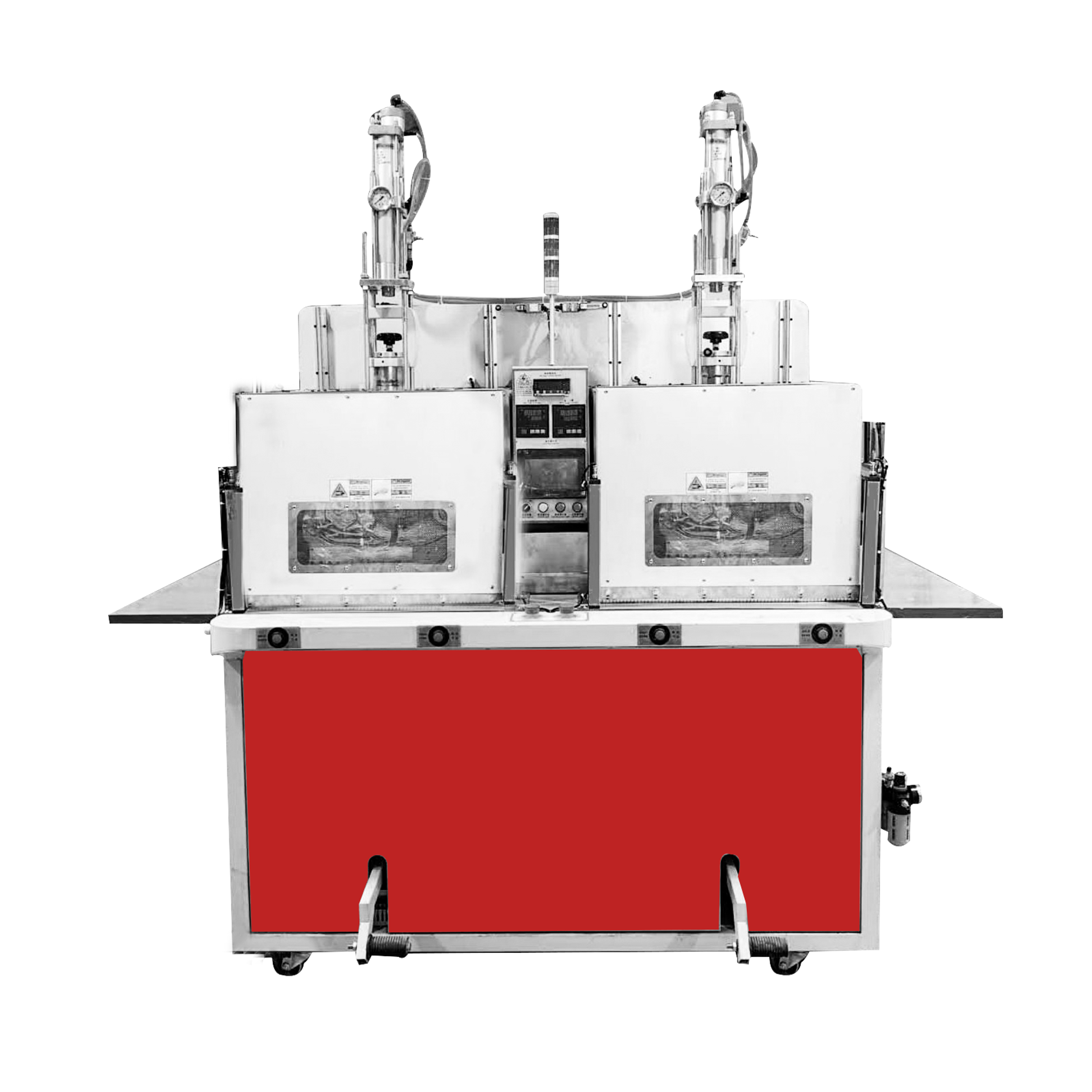

Double Head PVC Welding Machine High Frequency Machine for Plastic - Environmentally friendly pressurized

High efficiency, stability, and environmental protection upgrade! CH series double-head high-frequency welding machine

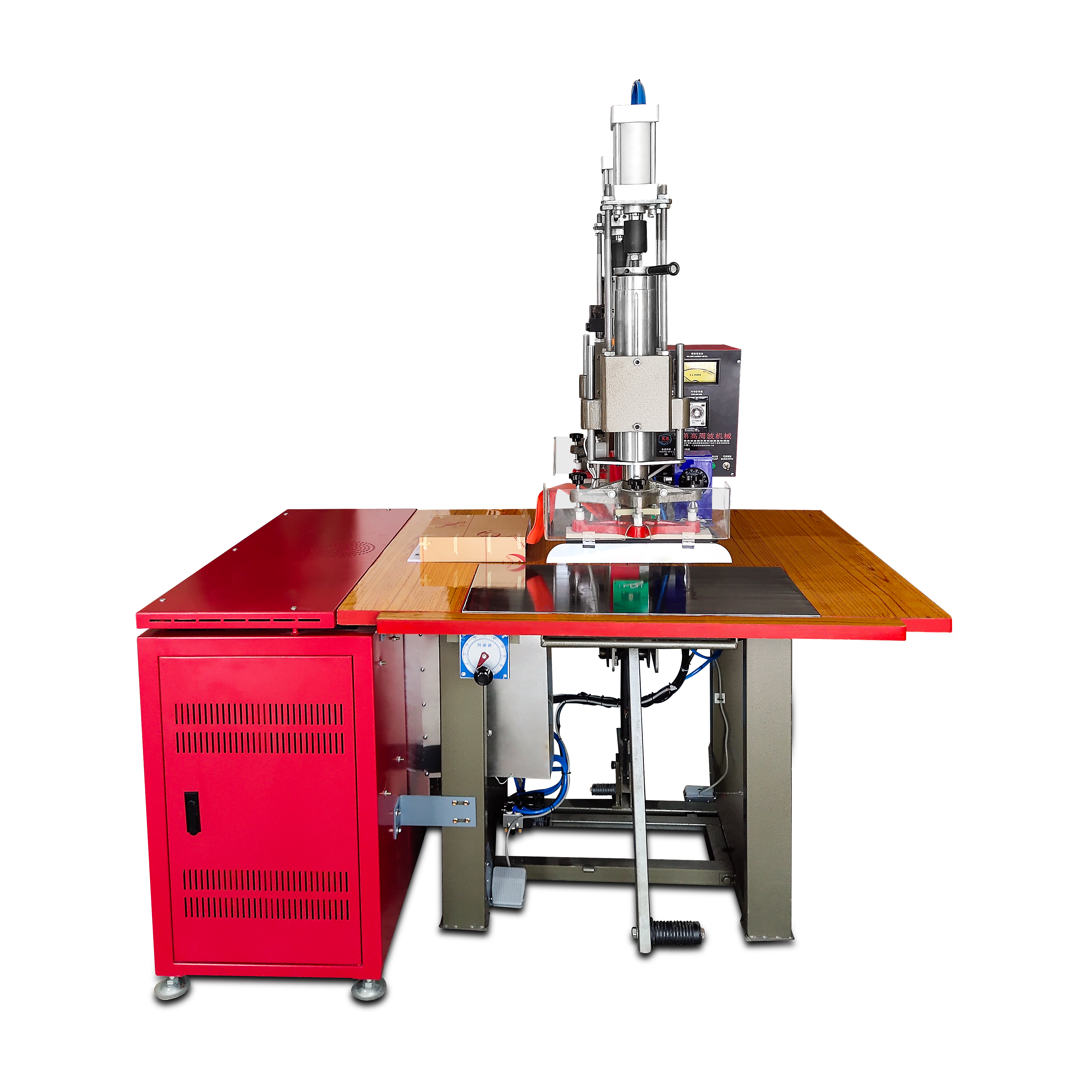

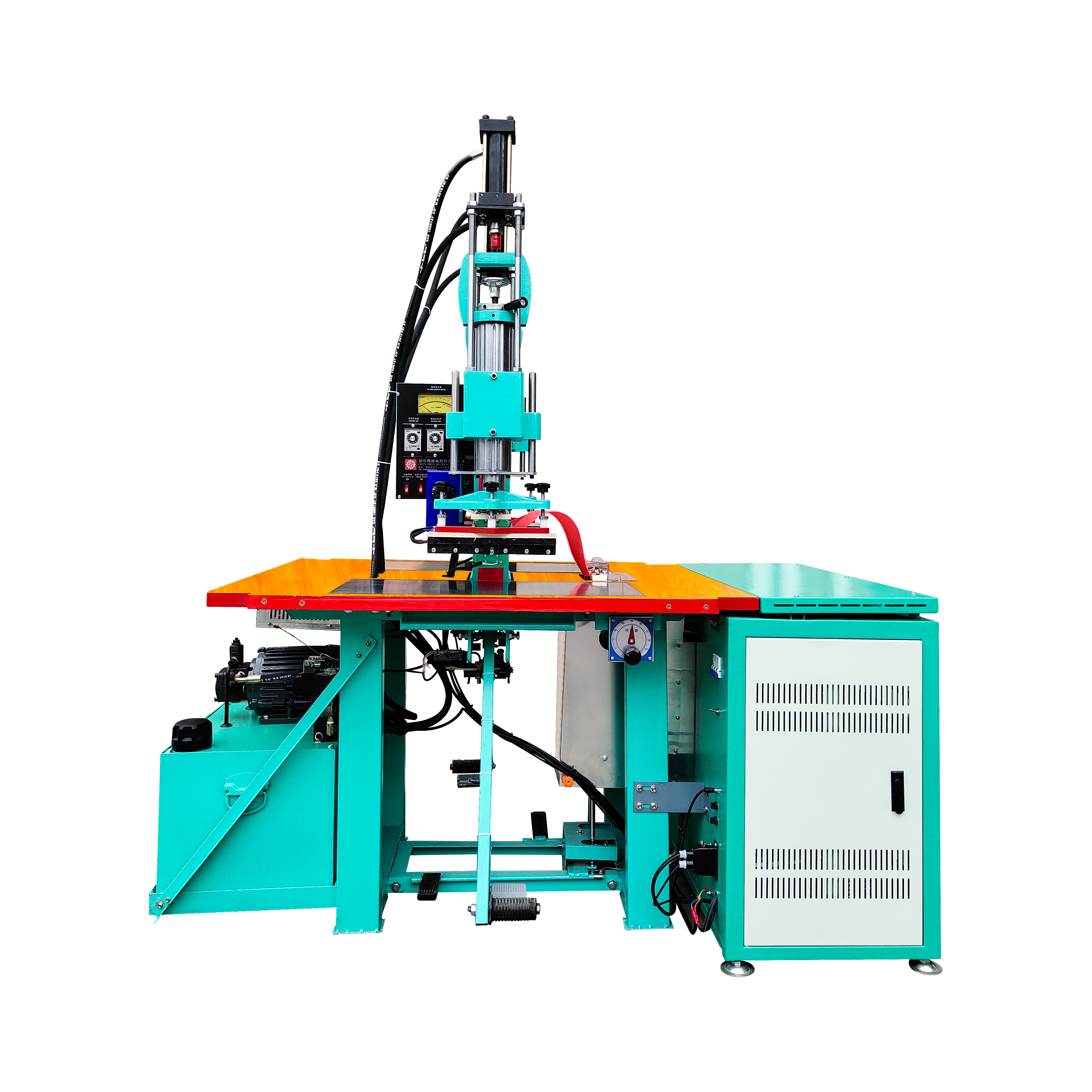

The CH series double-head high-frequency welding machine is designed for industrial high-efficiency welding and equipped with environmentally friendly boosting technology to meet diversified production needs. The full series includes three power models of 5KW, 8KW, and 12KW (CH-5000TAH, CH-8000TAH, CH-12000THA), which are suitable for production scenarios of different scales, with stable performance and energy saving.

Core parameters at a glance:

Output power: 5KW/8KW/12KW optional, flexible matching of production intensity

Machine voltage: 380V three-phase 5-wire, industrial-grade power adapter

Oscillation frequency: 27.12MHz high-frequency output, precise and efficient welding

Anti-spark system: 5557 safety protection, eliminating hidden dangers in operation

Working area: lower electrode 350*700mm, supporting large-size workpiece processing

Current limiting technology: 928 new current limiting system (24V+6V), stable current output

Model comparison and accessories highlights:

CH-5000TAH (5KW): lightweight design, power input 8KVA, electron tube 7T85RB, suitable for small and medium-sized processing.

CH-8000TAH (8KW): medium power first choice, power input 15KVA, electron tube 7T69RB, taking into account efficiency and energy consumption.

CH-12000THA (12KW): High-power flagship, power input 20KVA, electronic tube E3130, meet high-intensity continuous operation.

Product advantages:

✅ Environmentally friendly boost technology: reduce energy consumption, reduce carbon emissions, and meet green production standards.

✅ Safety protection upgrade: spark protection system + current limiting design, double guarantee of operation safety.

✅ Industrial-grade durability: appearance size 1750*1100*2250mm, stable structure, long-term operation without pressure.

Applicable fields:

Precise welding, welding and sealing processes in industries such as automotive accessories, automotive interiors, plastic packaging, medical supplies, stationery, electronic components, etc.