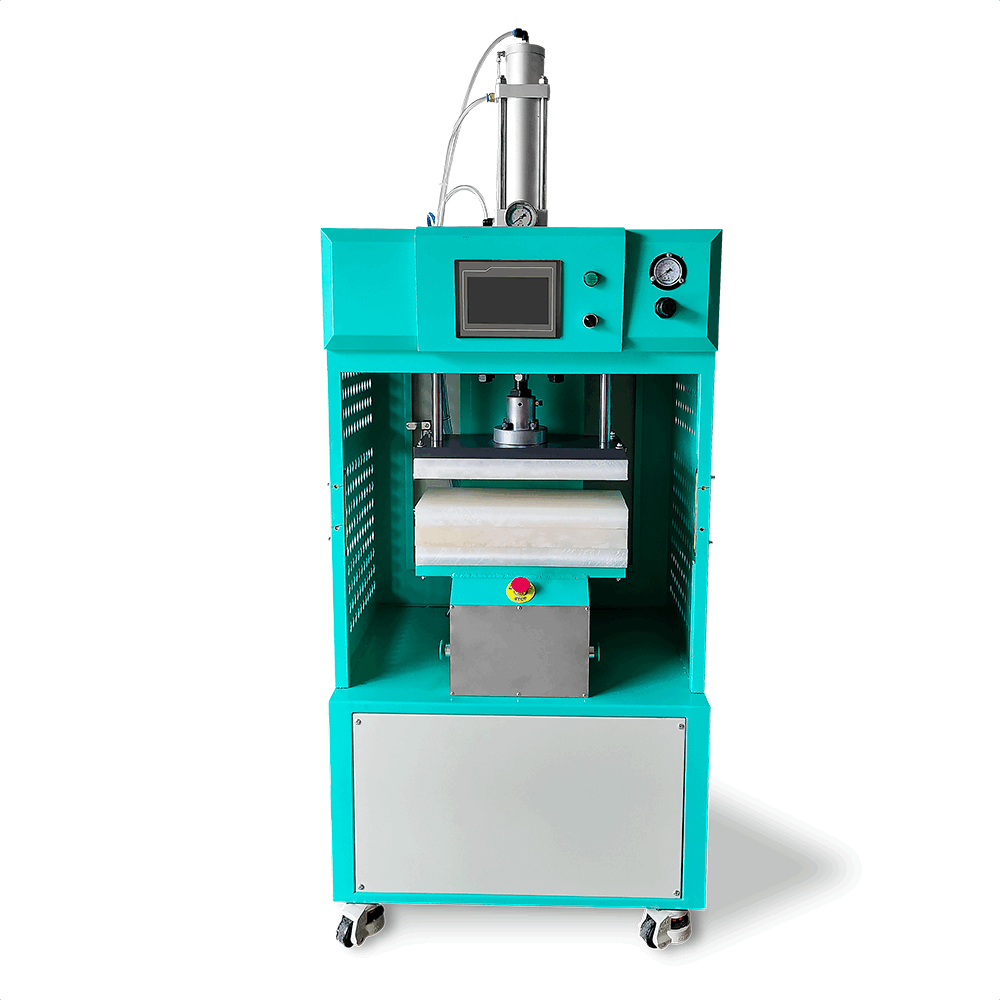

Automatic disc cutting machine

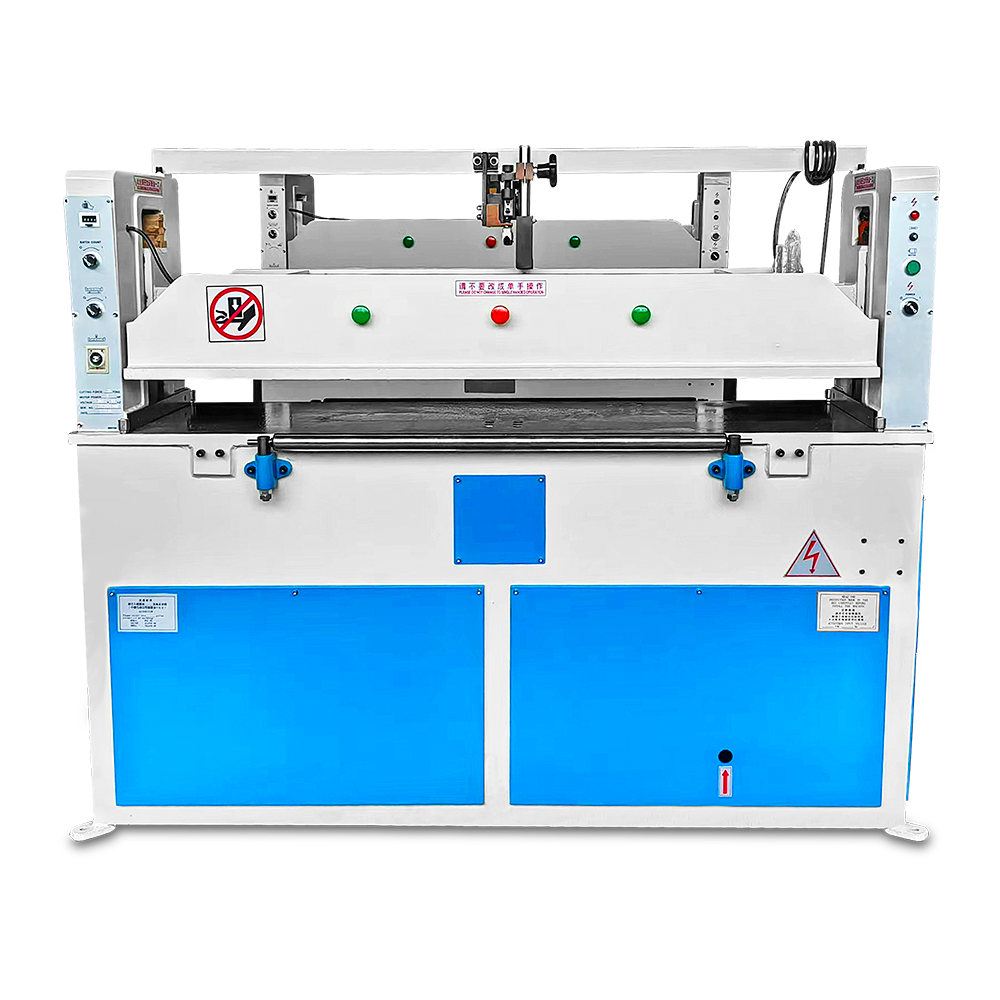

Double-station intelligent upgrade, cutting efficiency doubled!

The automatic disc cutting machine is specially designed for the upper, leather goods, and luggage industries. Through the 22-ton high pressure + double-station disc design, it can achieve seamless precision cutting and punching. Intelligent upgrade sitting operation, one person can work efficiently, production efficiency increased by 50%, labor costs directly reduced, it is the ultimate solution for bulk orders!

Core parameters and performance highlights:

Cutting performance: 22 tons maximum pressure, uniform cutting force, smooth edges without burrs.

Workstation design: Dual-station disc synchronous operation, seamless connection of production process, double efficiency.

Intelligent control: PLC+human-machine interface, one-key setting of pressure, stroke, speed parameters, real-time monitoring of operating status.

Working area: 330×430mm, suitable for processing medium and large workpieces such as uppers, leather, and luggage parts.

Stroke range: 100-150mm flexible adjustment, compatible with cutting requirements of materials of different thicknesses.

Power supply configuration: 380V three-phase five-wire industrial power supply, stable power, suitable for high-intensity production.

Appearance design: 1500×1200×2100mm compact body, saving plant space and easy to move.

Core advantages of the product:

✅ Efficient and labor-saving: Dual-station alternating operation, sitting operation reduces fatigue, and daily production capacity is increased by 50%.

✅ Precise and safe: infrared positioning + PLC intelligent control, cutting accuracy ±0.2mm, light curtain protection eliminates the risk of work-related injuries.

✅ Widely compatible: supports EVA, microfiber, leather, TPU and other materials, suitable for seamless cutting, punching, hollowing and other processes.

✅ Durable and energy-saving: industrial-grade hydraulic system, continuous operation life exceeds 100,000 hours, energy consumption is reduced by 30% year-on-year.

Applicable industries and scenarios:

Shoemaking industry: sports shoe upper cutting, sole punching, FLYWIRE seamless processing.

Leather goods and bags: leather cutting, zipper hole punching, decorative parts precision cutting.

Automotive interior: seat fabric cutting, sound insulation pad punching.

Home decoration: carpet cutting, fabric relief stamping.

Simplified operation process:

Parameter setting: select cutting pressure, stroke, and quantity through the human-machine interface.

Synchronous feeding: double-station discs alternately place materials to seamlessly connect the production rhythm.

One-button start: seated foot pedal trigger, 22 tons of pressure to instantly complete cutting and punching.

Finished product removal: automatic material return, neat edges without burrs, directly enter the quality inspection stage.