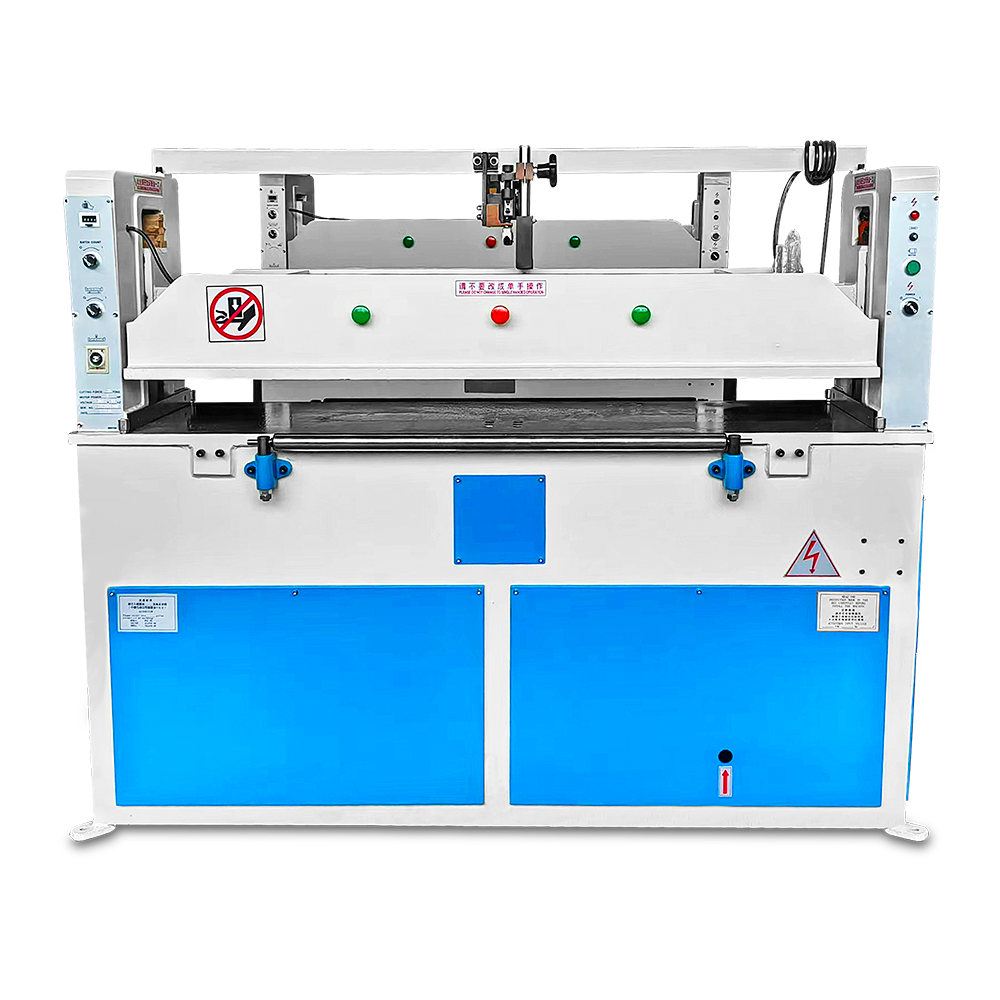

Flat cutting machine

High-pressure cutting, efficient and precise!

Designed for flexible materials such as leather, cloth, plastic, etc., it achieves fast and precise cutting through the 1200KG high-pressure cutting system. With a stable body and strong power, it is an ideal choice for small and medium-volume production and customized processing!

Core parameters and performance highlights:

Cutting performance: 1200KG high-voltage output, smooth cut without burrs, suitable for cutting multiple layers of materials at one time.

Power configuration: 3.75KW high-power motor, sufficient power, continuous operation efficiency increased by 30%.

Power adapter: 380V industrial voltage, stable power supply, adapted to the high-intensity production needs of the factory.

Body design:

Weight: 1600KG stable body, small operating vibration, cutting accuracy of ±0.5mm.

Dimensions: 1850×630×1580mm (length, width and height), compact layout saves workshop space.

Core advantages of the product:

✅ Efficient production: high-power drive, daily cutting volume increased by 40%, quick response to order needs.

✅ Wide compatibility: supports cutting of leather, EVA, microfiber, non-woven fabrics, TPU and other materials, thickness compatible with 0.5-30mm.

✅ Durable and reliable: industrial-grade steel body, wear-resistant die, service life of more than 100,000 hours.

✅ Convenient operation: one-button start design, manual loading + automatic cutting, novices can quickly get started.

Applicable industries and scenarios:

Shoemaking industry: upper cutting, sole material slitting, insole precision cutting.

Luggage manufacturing: leather cutting, zipper tape slitting, decorative parts processing.

Home decoration: carpet cutting, fabric curtain slitting, sofa fabric processing.

Automotive interior: seat leather cutting, sound insulation pad precision slitting.

Why choose?

High cost performance: taking into account efficiency and cost, the first choice for mass production of small and medium-sized enterprises.

Accurate and stable: high-pressure cutting force is evenly distributed, and multi-layer materials are not dislocated or deformed.

Safety protection: optional infrared light curtain or two-hand trigger button to ensure safe operation.