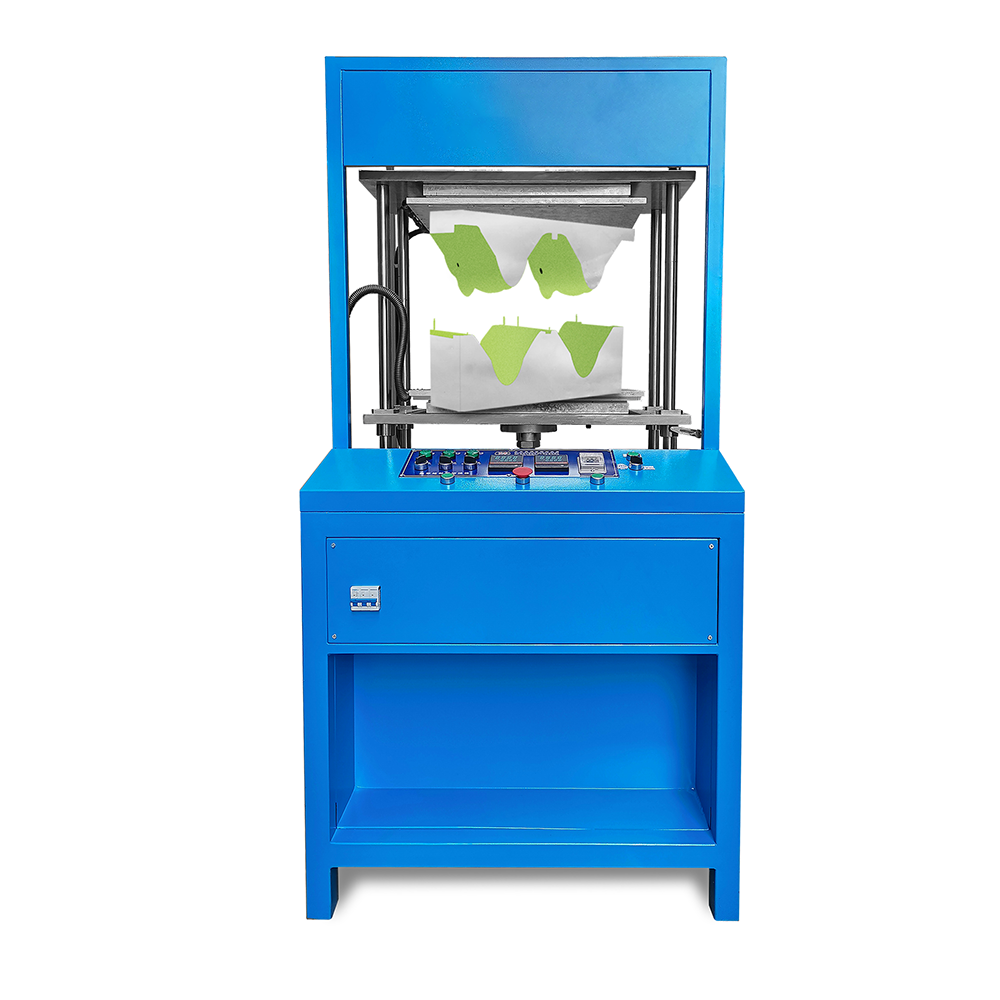

Sports shoes 3D back cover forming machine

Three-dimensional molding, precise fitting! BR-3D3550-2050 sports shoe 3D back cover molding machine

BR-3D3550-2050 sports shoe 3D back cover molding machine is specially designed for seamless lamination and 3D/4D/5D upper three-dimensional molding. It can achieve precise molding of complex upper structures through pneumatic high pressure and intelligent control. Single-station control, efficient and stable, helps high-end manufacturing of sports shoes and casual shoes!

Core parameters and performance highlights:

Power configuration:

Power: 9.8KW high-power motor, strong power, suitable for high-intensity continuous operation.

Air source: 6KG air source power, quick response, stable and uniform pressure output.

Operation design:

Working area: 350×550mm, compatible with the processing of sports shoe back cover, shoe tongue, decorative parts, etc.

Stroke range: 300-450mm flexible adjustment, suitable for different thickness materials and three-dimensional modeling requirements.

Structural design:

Cylinder: 200×500mm industrial-grade cylinder, resistant to high pressure, life of more than 100,000 times.

Body: 450KG stable body + 1000×800×2000mm compact size, smooth operation, saving space.

Core advantages of the product:

✅ Precise fitting: pneumatic pressure is evenly distributed, 3D upper three-dimensional molding without deformation, fitting accuracy ±0.3mm.

✅ High efficiency and labor saving: single-station one-button operation, manual material discharge + automatic shaping, production efficiency increased by 40%.

✅ Wide compatibility: Suitable for materials such as TPU, EVA, microfiber, hot melt film, etc., supporting sports shoe back cover, 4D flying woven upper, 5D embossed decoration and other processes.

✅ Durable and energy-saving: Industrial-grade pneumatic system, energy consumption reduced by 20%, continuous operation failure rate <0.5%.

Applicable scenarios and industries:

Sports shoe manufacturing: basketball shoe back cover shaping, running shoe 3D flying woven lamination, hiking shoe three-dimensional reinforcement.

Fashion shoes: 4D/5D decorative parts molding, upper embossed texture hot pressing.

Functional shoes: waterproof shoes seamless lamination, safety shoes protective layer fixed.

Simplified operation process:

Mold installation: Quickly replace customized molds to adapt to various upper designs.

Parameter setting: Adjust pressure, temperature, and time through the control panel.

Material positioning: Place the upper and substrate on a 350×550mm workbench and pneumatically clamp.

One-click molding: 6KG air source drive, 300-450mm stroke high pressure molding, 3D structure molding in one go.

Why choose BR-3D3550-2050?

High-precision guarantee: pneumatic system + intelligent temperature control, finished products without bubbles, no degumming, qualified rate ≥ 98%.

Flexible adaptation: support mold customization, switch production tasks within 5 minutes, and respond to small batch diversified orders.

Safe and reliable: automatic shutdown on overload + emergency stop button, double protection and safe operation.

Consult BR-3D3550-2050 now to get free proofing service and open a new era of high-end upper manufacturing!