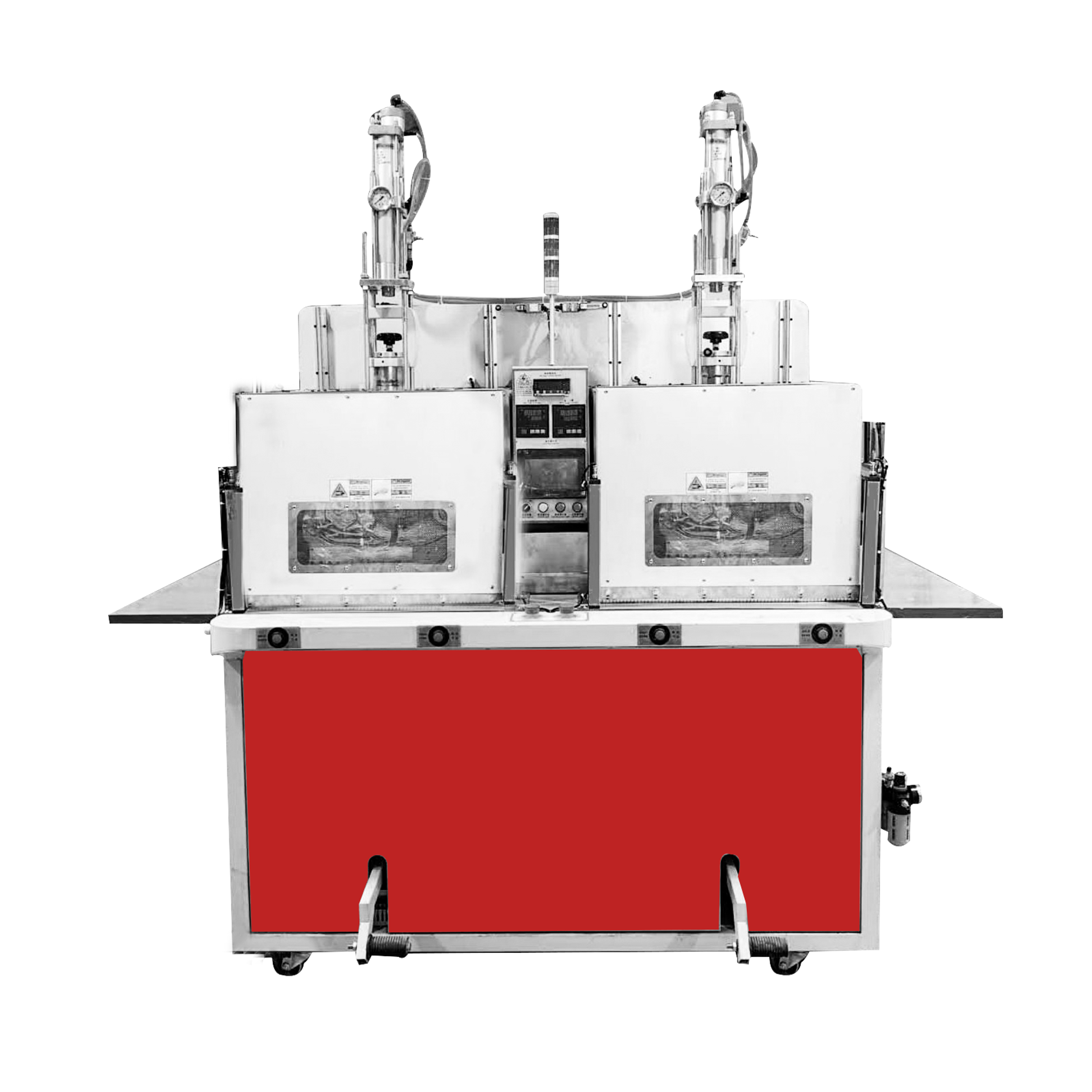

Single-sided double-head high frequency welding machine

Strong hydraulic pressure, high efficiency with two heads! BR series single-sided double-head high frequency welding machine.

BR series single-sided double-head high-frequency welding machine (hydraulic type) is specially designed for industrial efficient production. It is equipped with a hydraulic booster system and a double-head alternating operation mode, which greatly improves welding efficiency! The whole series covers four power levels of 5KW, 8KW, 10KW, and 12KW (BR-528TPH/828TPH/1028TBH/1228TPH), which can flexibly adapt to different production intensity requirements, with stable performance, power saving and durability.

Core parameters at a glance:

Output power: 5KW-12KW optional, precise matching of welding energy

Machine voltage: 380V three-phase 5-wire system, industrial-grade stable power supply

Oscillation frequency: 27.12MHz high-frequency output, fast welding without error

Maximum output: 350KG high voltage, ensuring firm and smooth welding

Working area: lower electrode 350*700mm, compatible with large-size workpiece processing

Current limiting technology: 928 system (24V+6V), stable current and safer

Control system: human-machine interface + smart button, parameter setting is clear at a glance

Function and applicable materials:

✅ Wide compatibility: supports welding of materials such as PVC, PU, PETG containing 30% plastic components, and can complete high-precision processes such as TPU hot cutting and cowhide branding.

✅ Full coverage of the industry: ideal choice for blister packaging sealing, hardware tool welding, stationery plastic sealing, inflatable toy seams, automotive parts welding and other fields!

Model comparison and performance highlights:

| Model | BR-528TPH (5KW) | BR-828TPH (8KW) | BR-1028TBH (10KW) | BR-1228TPH (12KW) |

|---|---|---|---|---|

| Power Input | 8KVA | 15KVA | 18KVA | 20KVA |

| Electron tube | Customized high efficiency pipe | Customized high efficiency pipe | Industrial grade wear-resistant pipe | E3130 Ultimate tube |

| Applicable scenarios | Lightweight precision welding | Medium to high load production | High-intensity continuous operation | High-power industrial processing |

Core advantages of the product:

Hydraulic boost technology: 350KG high-pressure output, uniform welding pressure, and the finished product is firm and flawless.

Efficient operation of dual heads: manual discharge + alternating operation of dual stations, production efficiency increased by 40%, and labor costs reduced!

Intelligent safety protection: LCD screen precise temperature control (±1℃), anti-ignition system + current limiting design, double guarantee of operation safety.

Energy saving and environmental protection: high-frequency power is stable, energy consumption is reduced by 20%, in line with green production standards.

Simplified operation process:

Manual discharge: dual-station synchronous preparation, seamless connection of production rhythm.

One-button start: foot positioning + double-hand trigger button, high-frequency instant penetration welding.

Automatic completion: time control of melting/removal, workpiece is not hot, zero risk of operation.

Applicable industries and scenarios:

Packaging industry: blister sealing, blister welding

Hardware manufacturing: tool accessories welding, plastic edge sealing

Toys and stationery: inflatable toy seams, stationery plastic sealing

Automotive parts: rubber parts welding, interior fixing

Consult now to get the exclusive solution of BR series hydraulic high-frequency welding machine and start a new chapter of efficient production!