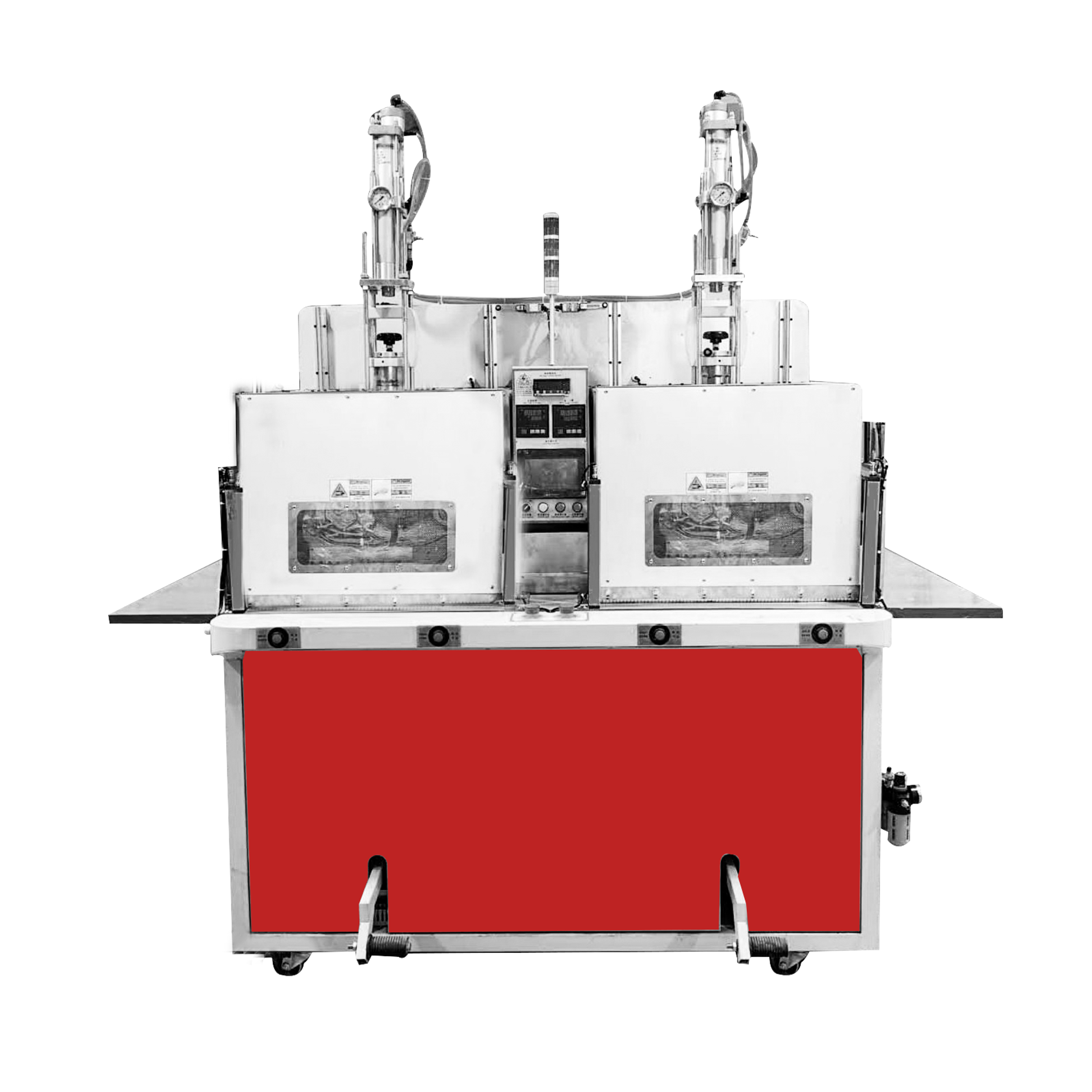

Single-sided double-head vertical booster cylinder high frequency

Single person, double workstation, double efficiency! BR series single-sided double-head vertical high-frequency welding machine (supercharged version)

Core parameters at a glance:

Output power: 5KW-12KW flexible selection to meet different welding strengths

Machine voltage: 380V three-phase 5-wire system, industrial-grade stable power supply

Oscillation frequency: 27.12MHz high-frequency output, precise welding without error

Maximum output: 1900KG high voltage to ensure welding firmness

Working area: lower electrode 350*500mm, compatible with small and medium-sized workpiece processing

Anti-spark system: multi-level protection design to prevent spark damage

Control system: human-machine interface + PLC intelligent control, precise and convenient operation

Appearance size: L1750W1100H2400mm, vertical structure saves space

Function and applicable materials:

✅ Wide compatibility: supports welding of materials such as PVC, PU, PETG containing 30% plastic components, and can complete high-precision processes such as TPU cooked cutting and cowhide branding.

✅ Full coverage of the industry: ideal solutions for blister packaging, hardware tools, stationery manufacturing, inflatable toys, auto parts, shoe embossing and other fields!

Model comparison and performance highlights:

| Model | BR-557TPH (5KW) | BR-857TPH (8KW) | BR-1057TPH (10KW) | BR-1257TPH (12KW) |

|---|---|---|---|---|

| Power input | 8KVA | 15KVA | 18KVA | 20KVA |

| Electronic tube | Customized model | Customized model | Customized model | E3130 high-performance tube |

| Applicable scenarios | Lightweight precision welding | Medium and high-load production | High-intensity continuous operation | Industrial-grade high-power processing |

Core advantages of the product:

High efficiency and labor saving: single-person double-station operation, seamless connection of alternating operations, production efficiency increased by 50%, and labor costs reduced by 30%!

Intelligent control: human-machine interaction interface + PLC system, LCD screen precise temperature control (±1℃), one-button parameter setting, zero threshold for operation.

Safe and durable: 1900KG high-voltage output + anti-spark system, firm welding without damage, and equipment life extended by 20%.

Energy saving and environmental protection: high-frequency power is stable, energy consumption is reduced by 25%, in line with green production standards.

Simplified operation process:

Manual material discharge: dual-station synchronous material preparation, no need to wait.

Foot start: right foot positioning, double-hand trigger button, high-frequency instant penetration welding.

Automatic control: precise time setting, integrated fusing/cutting/retrieving, and workpieces are not hot.

Applicable industries and scenarios:

Packaging industry: blister sealing, blister welding

Hardware manufacturing: tool accessories welding, plastic edge sealing

Toys and stationery: inflatable toy seams, stationery plastic sealing

Shoes and leather goods: upper embossing, leather branding

Consult now to get exclusive solutions for the BR series high-frequency welding machine and start a new mode of efficient and labor-saving production!