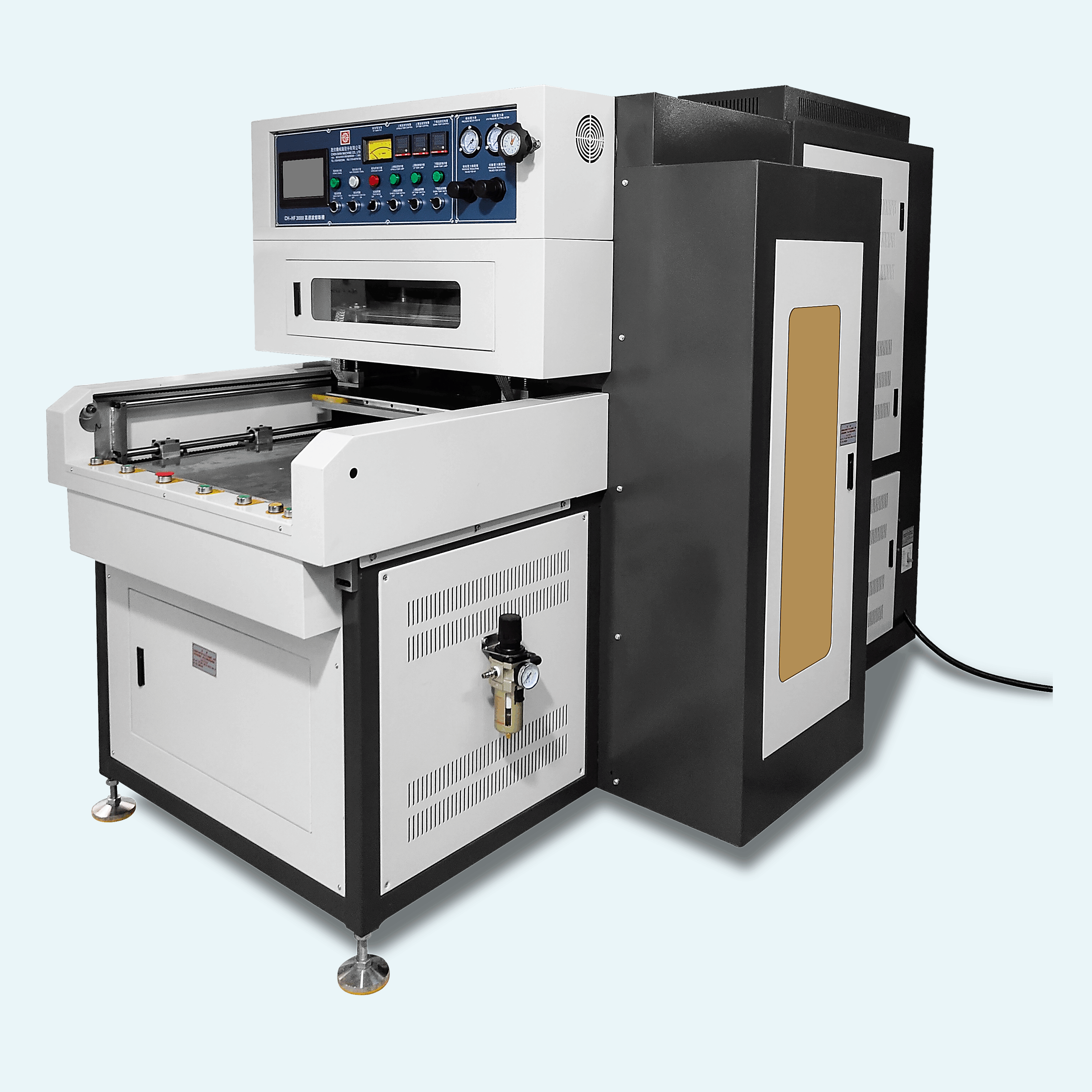

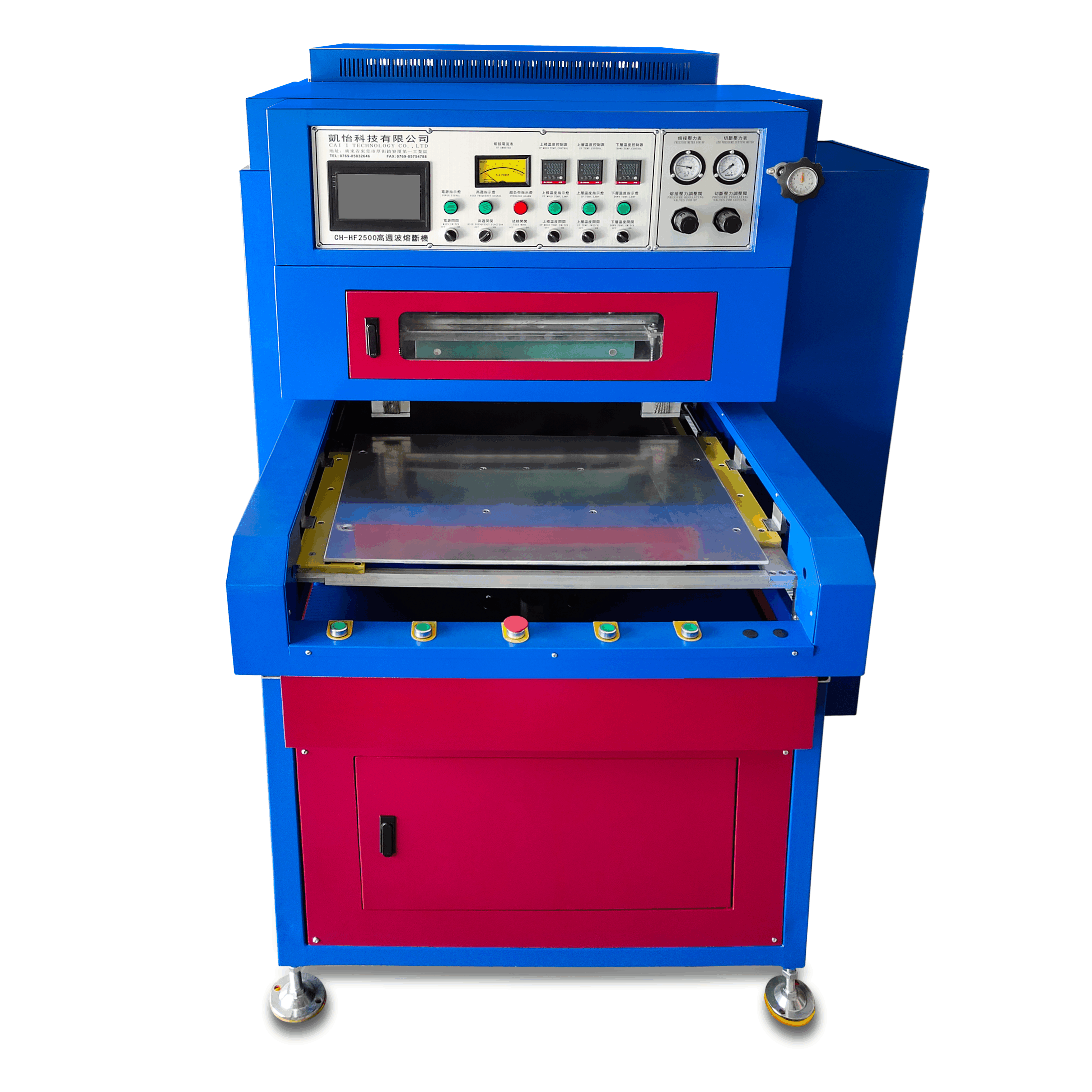

Front and rear double-station slide synchronous fusing machine

High efficiency and synchronization, one-step fusing! BR-40601548THKG high-frequency synchronous fusing machine

The BR-40601548THKG front and rear double-station slide synchronous fusing machine is specially designed for industries such as shoes, bags, and trademarks. It uses high-frequency electric field technology to achieve material welding + synchronous cutting, without secondary processing, and the finished product has smooth edges without burrs. The front and rear double-station slide supports one person's efficient operation, saves space, and improves efficiency by 60%. It is the ultimate solution for mass production!

Core parameters and performance highlights:

Electrical parameters: 15KW power, 380V three-phase five-wire 60Hz power supply, industrial-grade stable power output.

Pressure performance: 48T high-voltage welding, ensuring firm bonding of materials, precise synchronous cutting without residue.

Working area:

Upper mold: 400×600mm

Lower mold: 500×750mm

Suitable for processing medium and large workpieces such as uppers, bags, trademarks, etc.

Safety protection: 5557 high-sensitivity protection system, abnormal state response in seconds, ensuring equipment and operation safety.

Appearance design: double-station structure of the slide, high space utilization, smooth operation line.

Core functions and advantages:

✅ Synchronous fusing technology: high-frequency electric field welding + cutting is completed in one step, avoiding secondary processing loss, and the qualified rate of finished products is as high as 99%.

✅ Dual-station efficient production: The front and rear slides are operated independently, supporting one person to work synchronously, doubling the production capacity.

✅ Wide compatibility: Suitable for materials such as TPU, PET environmentally friendly materials, leather, non-woven fabrics, etc., to meet the process requirements of NO SEW seamless bonding, FLYWIRE uppers, nameplate embossing, etc.

✅ Intelligent temperature control: High-frequency oscillation frequency is stable, hot melting is uniform, and material deformation or coking is avoided.

Applicable industries and scenarios:

Shoemaking industry: sports shoe upper welding, sole TPU hot cutting, FLYWIRE seamless bonding.

Bag manufacturing: leather bag seam welding, zipper base fixing, trademark synchronous cutting.

Clothing accessories: trademark embossing, clothing decorative parts high-frequency welding.

Industrial accessories: plastic nameplate, electronic equipment insulation layer processing.

Product core advantages:

Efficient and time-saving: welding and cutting are completed simultaneously, the processing process is shortened by 50%, and the labor cost is directly reduced.

Accurate and durable: high-precision slide positioning (±0.2mm), industrial-grade fuselage structure, continuous operation life exceeds 80,000 hours.

Safe and worry-free: The 5557 system monitors current and temperature in real time, automatically cuts off power in case of overload, and operates at zero risk.

Flexible adaptation: Quick mold change design, switch production tasks within 5 minutes, and respond to diversified orders.

Consult BR-40601548THKG synchronous fusing machine now to obtain industry customized solutions and start a new mode of efficient and waste-free production!